Facilities across the U.S. have realized the importance of infection prevention and mitigating cross-contamination.

One of the easiest and most effective ways to prevent germ spread and cross-contamination is with a color-coded microfiber program.

What is a color-coded microfiber program?

With a color-coded microfiber program, a different-colored microfiber cloth or mop should be used for a specific cleaning task, job, or area in your facility.

A color-coded microfiber program offers several benefits. The main benefit being infection control.

Designated areas, like restrooms, will have one color while other areas, like food prep stations, will have another color, eliminating the chance of contamination.

A color-coded microfiber program not only creates consistency across different cleaning teams or departments but also helps simplify staff training and even helps bridge possible language barriers.

In the article and video below, we’ll review the benefits of a color-coded microfiber program and how to set one up.

To begin, we’ll provide an overview of microfiber, and how it differs from traditional terry rags or cloths.

Microfiber cloths are made up of tightly woven synthetic fibers, typically a blend of polyester and nylon.

Microfiber grabs particles and contaminants from a surface and traps them in its fiber, whereas traditional cloths and rags simply redistribute the soils to another area. Using the same cloth is especially dangerous if it is being used in two different areas, like the restroom and the kitchen.

Benefits of a Color-Coded Microfiber Program

Lower Risk of Cross-Contamination

Many times, cross-contamination is accidental because your staff doesn’t realize a cloth has already been used in an area that could spread bacteria.

You and your staff can help prevent cross-contamination by limiting where a cloth is used based on color. For example, germs can be spread between areas when the same mop or cloth is used in a restroom and a food prep station.

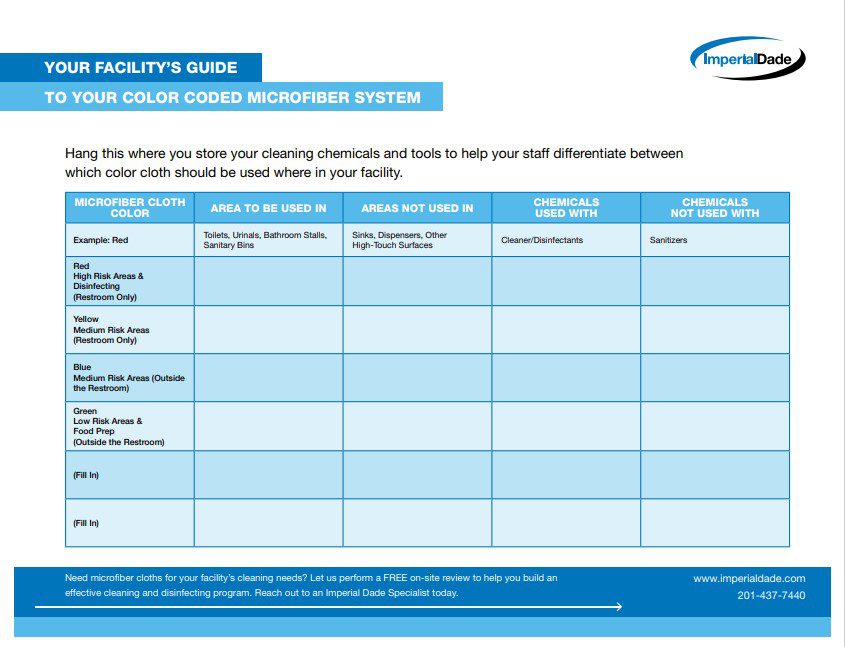

Using cloths or mops in multiple areas or across different surfaces can lead to cross-contamination. Color-coded microfiber systems can help avoid this and other issues. Download our FREE chart. You can use this chart to educate staff on what color microfiber should be used in specific areas or surfaces in your facility!

Reduce Germ Spread

Simply touching a contaminated surface with a cloth and then coming into contact with another surface can quickly and easily spread germs.

Color coding is an easy way to reduce the transfer of bacteria from one area to another.

Simplify Training

Implementing a color-coded cleaning program using different colored cloths to represent specific tasks, jobs or areas will help to eliminate confusion among your staff.

Staff turnover is inevitable and this can lead to gaps in training. While regular training is recommended, a color-coded program can help make things for staff of all levels or departments clear.

Eliminate Language Barriers

Sometimes even with the best communicators, things can be lost in translation. Color is somewhat of a universal language.

Seeing different colors signals to staff, regardless of an employee’s native language, that there is a difference in the cloth’s purpose. Unique colors will remind people they should be used for distinct cleaning tasks or areas.

General Guidelines for a Color-Coded Microfiber Program

What colors should be used for each cleaning task?

While there are no set standards for a color-coded microfiber program, many facilities follow the general guidelines for use below.

How to color-code?

A color-coded microfiber program can be used in two ways:

- To clean a combination of areas i.e. different colors by room

- To clean different surfaces in a room based on risk i.e. toilets versus mirrors

While you can choose to set different colors for unique areas like the kitchen and the restroom, you can also choose to use different colors within one room to further lessen germ spread.

If you choose to use multiple color cloths within an area, make sure staff do not mix up the cloths to be used in one cleaning area. This is most commonly done in the restroom.

For example, your cleaning staff may use red microfiber to clean around toilets, urinals, and other high-risk areas and blue for general cleaning in the restroom like mirrors and glass windows.

There is no limit to the number of colors in a program. However, in general, the most common colors in a program are red, yellow, green, and blue.

Each color is used for a different area based on the level of risk. Here’s an example program:

Red:

High Risk Areas & Disinfecting (Restroom Only)

Red microfiber cloths are typically used for the areas with the highest risk of cross-contamination and most likely to spread infection.

- Toilets

- Urinals

- Bathroom Stalls

- Sanitary Bins

Yellow:

Medium Risk Areas (Restroom Only)

Yellow is used in areas of the next greatest concern.

- Sinks

- Soap Dispensers

- Paper Towel Dispensers

- Door Handles

- Grab Bars

Blue:

Medium Risk Areas (Outside the Restroom)

Blue microfiber is typically used for general cleaning in lower-risk areas or surfaces.

- Glass

- Mirrors

- Door Handles/Knobs

- Water Fountains

- Elevator Buttons

- Handrails

Green:

Low Risk Areas & Food Prep (Outside the Restroom)

Green-colored microfiber is used in food prep areas.

- Desks

- Tables

- Keyboard/Computer Mouse

- Countertops

- Phones

- Chair Arms

Final Thoughts

A color-coded microfiber program is designed to reduce the chance of cross-contamination and infection by making it clear where a certain cleaning tool should be used.

Implementing a new cleaning program, even if it is as simple as requiring certain color cloths for specific tasks can sometimes be difficult. Cleaning teams with veteran staff who are used to doing things a certain way may be hesitant to adopt this new system. It is critical to reinforce the importance and benefits of the system.

To help remind and reinforce the system you can post a color-coding chart to serve as a visual reminder.

There are numerous advantages to a color-coded microfiber program, and Imperial Dade can help you implement a program if you’re located in the United States, Puerto Rico, the Caribbean, or Canada.

Imperial Dade locations offer a variety of microfiber cleaning tools to lower the risk of cross-contamination in your facility.

Contact a specialist today for an in-person or virtual evaluation of your facility to help you optimize your cleaning program.