Commercial floor buffers and burnishers are used to improve floor appearance throughout your facility.

To remain effective, floor pads need to be periodically replaced after wear, and they should be removed after each maintenance procedure to avoid damage. In either case, if a floor pad is not properly removed and installed each time, it can negatively affect floor appearance, worker productivity, the safety of your occupants, and the life of your floor machine.

Below, we will review the importance of properly installing and removing floor pads and the steps to follow.

On most floor buffers, the pad driver and pad will need to be removed and cleaned after each floor care procedure. However, on some floor buffers, the machine head can be tilted up for storage so that the machine is not sitting on the floor pad. Similar to buffers, floor burnishers should not sit on the pad. Depending on the manufacturer, the pad can either be raised or removed.

Pro Tip: If the machine head is not lifted from the floor, or the pad is not removed before storage, the floor pad will likely become compressed and uneven. Uneven floor pads will cause the machine to vibrate and produce an inconsistent shine on the floor, ultimately creating more work for your staff.

Floor pads on both burnishers and buffers will also need to be replaced when they become worn or damaged. If they are not replaced, they can create a hazard to your staff and occupants.

With use, floor pads can become stretched and loosen on the machine. If this happens, the pad can eventually fly off the machine and hit staff, occupants, and other fixtures.

Additionally, when the pad begins to wear or gets damaged, it loses effectiveness. If the floor pad is no longer doing its job, such as reaching the desired shine during floor burnishing, your staff will have to spend more time making additional passes over the floor.

| Floor Pad | Pad Driver | Pad Retainer |

| |

How to Install a Floor Pad on a Floor Buffer

Step 1: Unplug the Machine

Step 2: Lock the Machine Handle in Place

Step 3: Tilt the Machine Back

Step 4: Center Pad on Pad Driver and Install

Step 1: Unplug the Machine

Before preparing to install or replace the floor pad on a commercial floor buffer unplug the machine.

Separating the machine from the power source eliminates any risk of the machine accidentally turning on during pad installation.

Step 2: Lock the Machine Handle in Place

Lock the floor buffer handle so that you can tilt the machine back. When locked, you will be able to easily tilt the machine back.

Step 3: Tilt the Machine Back

Gently, tilt the machine back and rest the handle on the ground. The bottom of the machine should be at a 90-degree angle to the floor for easy access to the pad driver.

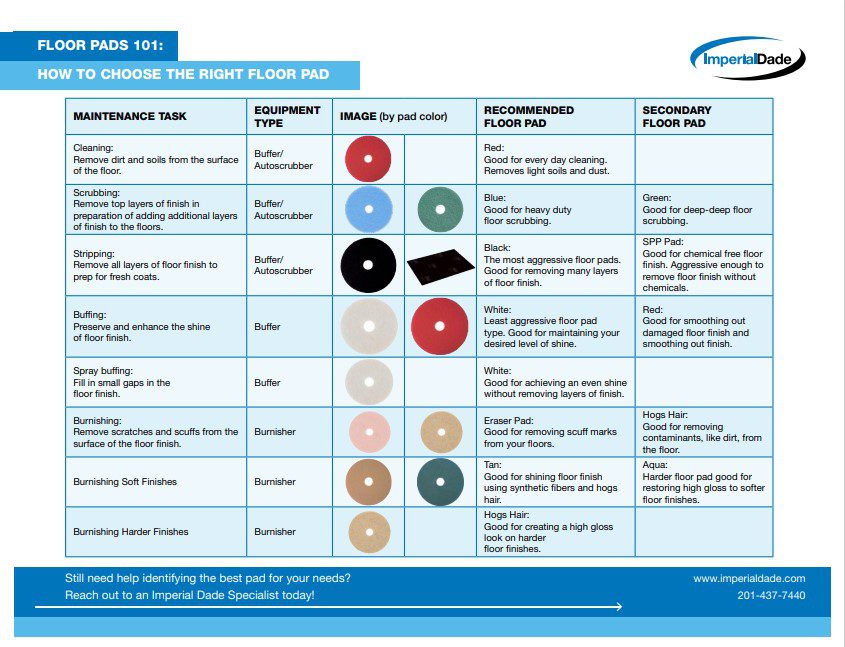

Not sure you’re using the right floor pad? Download our FREE poster:

Step 4: Center Pad on Pad Driver

The grips on the machine’s pad driver will hold the pad firmly in place.

It is critical to make sure the pad is centered around the circle slot in the middle of the pad driver.

Warning: If the pad is not centered on the pad driver, it will cause the machine to wobble. When the machine produces increased vibrations, the operator will have a harder time controlling the machine, forcing them to exert more energy. Increased fatigue will lead to decreased productivity. A wobbly machine can negatively effect the results of a floor care procedure. Additionally, when the pad is not centered, it will increase the noise level of the machine which can be disturbing to occupants.

Pro Tip: If the pad driver is not secured to the machine, you will need to install the pad driver on the machine head. To install the pad driver, align the clutch plate with the center of the machine and twist to lock.

How to Install a Floor Pad on a Floor Burnisher

Step 1: Unplug or Turn Off (Battery-Operated)

Step 2: Tilt the Machine Back

Step 3: Center the Pad on the Machine

Step 4: Attach the Pad Retainer

Step 1: Unplug or Turn Off (Battery-Operated)

Commercial floor burnishers can be battery operated or cord-electric. To replace the floor pad on a burnisher, first unplug the machine if it is cord-electric or turn off the power switch for a battery burnisher.

It is critical to turn off power to the machine to mitigate the risk of the machine accidentally turning on during pad installation.

Step 2: Tilt the Machine Back

Depending on the brand and type of floor burnisher you will access the floor pad in one of two ways.

For an electric floor burnisher, tilt the machine back and rest the handle on the ground.

For a battery burnisher, you will either tilt the machine back or the entire head will swing up for access.

Step 3: Center the Pad on the Machine

Apply the pad to the pad driver. The pad should be centered from the outside of the pad driver. Meaning, check to make sure it is even along the outer edges.

Pro Tip: Always spin the pad driver to see if the pad is properly centered. If the pad is off-center, the pad will wobble. If the pad is wobbling, remove the pad and recenter.

Step 4: Attach the Pad Retainer

After centering the floor pad to the pad driver, insert the pad retainer. The pad retainer will need to be either screwed in or snapped in depending on the manufacturer.

Pro Tip: The pad should always be applied to the pad driver before inserting the pad retainer. If you insert the pad retainer into the pad before applying it to the pad driver it increases the likelihood that the pad will not be centered.

Warning: If the pad retainer is improperly installed or not tightened onto the holder, it will fail to hold the pad in place. Meaning, the pad can fly off the machine at high speeds and can injure people and damage other products or fixtures in the area. The retainer should be screwed in as tightly as possible. The pad retainer should create a bevel across the floor pad so that the plastic pad retainer does not hit the floor. If the retainer is not screwed in tight enough and is allowed to hit the floor, it will create scratches.

Everything you need to know about commercial floor burnishers including types, sizes, specs, & more!

How to Remove a Floor Pad From a Floor Buffer

Step 1: Unplug the Machine

Step 2: Lock the Machine Handle in Place

Step 3: Tilt the Machine Back

Step 4: Remove Pad Driver

Step 5: Pull Pad from Pad Driver

Step 1: Unplug the Machine

When removing a floor pad from a floor buffer, always unplug the machine.

Disconnecting the power source will ensure that the machine will not accidentally turn on during pad removal.

Step 2: Lock the Machine Handle in Place

Lock the floor buffer handle so that you can easily tilt the machine back.

Step 3: Tilt the Machine Back

Rest the floor machine’s handle on the ground. By placing the machine parallel to the floor you will be able to easily access the pad driver and floor pad.

Warning: Do not try to remove the floor pad without laying the floor machine down. The machine will not be stable and can fall, causing injury to you and damage to the floor and the machine.

Step 4: Remove Pad Driver

Twist the pad driver until it unlocks.

Step 5: Pull Pad from Pad Driver

Simply peel the floor pad from the grips of the pad driver.

Pro Tip: Some buffers will have a pad retainer that needs to be unscrewed before the pad can be pulled from the grips.

How to Remove a Floor Pad From a Floor Burnisher

Step 1: Unplug the Machine or Turn Off Power

Step 2: Tilt the Machine Back

Step 3: Remove Pad Retainer

Step 4: Pull Pad from Pad Driver

Step 1: Unplug the Machine or Turn Off Power

Before removing the floor pad on a commercial floor burnisher unplug the machine or turn off the power for a battery burnisher.

Separating the machine from the power source eliminates any risk of the machine accidentally turning on during pad removal.

Step 2: Tilt the Machine Back

As mentioned above, depending on the brand and machine type you will access the pad one of two ways. If you have an electric burnisher, tilt the machine back and rest the handle on the ground.

If you have a battery burnisher, depending on the brand you will either tilt the machine back or fold the entire head up for access to the pad.

Step 3: Remove Pad Retainer

The floor pad can only be removed once the pad retainer is removed.

Do not try to remove the pad without unscrewing or unsnapping the pad retainer.

Step 4: Pull Pad from Pad Driver

After removing the pad retainer, peel the floor pad from the grips of the pad driver.

Final Thoughts

The proper installation of a floor pad every time is critical to achieving desired results, ensuring employee and occupant safety, and maintaining worker efficiency.

Janitorial cleaning equipment is an integral part of your facility’s cleaning operations. It is critical to ensure that staff is trained on the proper use and maintenance of equipment and that the equipment is working properly when you need it most.

Imperial Dade locations offer a variety of free training courses to educate staff on the latest equipment. Our hands-on courses allow attendees to interact with equipment while reinforcing the most up-to-date cleaning and maintenance practices.

Contact an Imperial Dade Specialist today to schedule training for your janitorial staff if you’re located in the United States, Puerto Rico, or the Caribbean. Imperial Dade can also provide service for your floor cleaning equipment to ensure that your equipment is always operating at peak performance, saving you time and money, and ultimately improving your business’ bottom line.

![How to Change a Floor Pad on a Floor Buffer or Burnisher [+Steps]](https://imperialdade.blog/wp-content/uploads/2022/12/BU800-Pad-Removal-1-1024x418.jpg)