In recent years, the demand for more sustainable packaging has been growing steadily. As a result, many companies have adopted the use of molded fiber and bagasse food packaging.

Molded fiber and bagasse are considered some of the most environmentally friendly food packaging options because they “close the loop”. Molded fiber is constructed from post-consumer content, and bagasse is made from renewable resources like sugarcane or wheatgrass. When they are discarded, the majority of these products can be commercially composted, breaking down and leaving a smaller footprint on the earth.

Molded fiber and bagasse became a signal to consumers that a food establishment cares about the environment. Many health-conscious establishments like healthcare facilities, fast-casual dining, and farm-to-table restaurants use this as their food packaging of choice.

But a recent article by the New Food Economy has alerted consumers and foodservice operators of the use of PFAS in molded fiber and bagasse food packaging.

The news sparked a string of attention-grabbing headlines like, “The bowls at Chipotle and Sweetgreen are supposed to be compostable. They contain cancer-linked “forever chemicals” and “Cancer-linked chemicals served in your lunch bowl?”

As a result, consumers and business owners may be questioning the health effects and sustainability claims of these food packaging products.

In this article, we will define PFAS and help explain its role in food packaging materials. We will also provide some alternative food packaging materials for those who currently purchase molded fiber and bagasse and are considering a change due to sustainability or consumer concerns.

What is PFAS?

According to the EPA, PFAS, or Per- and polyfluoroalkyl substances, are a group of man-made chemicals that have been in use around the globe, including in the United States, since the 1940s. PFAS are found in several consumer products such as non-stick pans, food packaging, and stain or water repellent fabrics.

PFAS chemicals are commonly added to bagasse or molded fiber food packaging because it gives the packaging a greater resistance to moisture, oil, and grease.

If you are using a molded fiber or bagasse product, it most likely contains PFAS. Without PFAS, they would quickly get soggy and break down.

PFAS chemicals are a group of 4,000 fluorinated compounds that DO NOT degrade naturally. There are several different types of PFAS, and each is unique.

Many recent articles, like the ones mentioned above, do not clearly distinguish between the different types of PFAS compounds, which can be misleading. There are two types of PFAS: long-chain and short-chain.

Studies found that some long-chain PFAS are linked to several adverse health effects. After the FDA released their findings, manufacturers voluntarily stopped producing and distributing these products as of October 1, 2011.

When long-chain PFAS were removed from the market, manufacturers switched to other approved types of PFAS, like short-chain PFAS. Short-chain PFAS were developed as an alternative to long-chain PFAS.

The FDA has approved certain types of PFAS for use in food contact packaging.

Is Molded Fiber or Bagasse Food Packaging Safe?

Food packaging safety is monitored by the FDA. The FDA must approve a substance before it can come into contact with food.

Federal law requires companies who wish to use a food contact substance to submit Food Contact Notifications (FCNs) to FDA at least 120 days prior to marketing the product.

According to the New Food Economy article, there are currently 62 PFAS approved by the FDA for use in food contact products.

The PFAS used in food contact packaging today has been tested and according to a statement released by the FDA on June 11th, “based on the best available current science, the FDA does not have any indication that these substances are a human health concern, in other words a food safety risk in human food, at the levels found in this limited sampling.”

To date, the FDA has not changed their stance on PFAS used in food contact products and has not banned the PFAS currently used, but continues to research the effects of PFAS on the environment and human health to determine if future action is needed.

While the FDA has approved certain types of PFAS for the use in food packaging, some states are putting their own bans and regulations in place regarding the use of PFAS.

Check out this up-to-date map to see which states are implementing PFAS bans.

Are Molded Fiber and Bagasse Compostable if they Contain PFAS?

Molded fiber is a signal of sustainability because it can be commercially composted. But, when the concerns of PFAS were raised, questions about compostability soon followed because PFAS compounds do not degrade naturally.

Prior to 2017, commercial composters did not have standards regarding the presence of PFAS in food packaging.

Pro Tip: The level of fluorine in a product can be used to determine if the product was treated with PFAS.

Third-party certification institutes, like BPI (Biodegradable Products Institute) and Cedar Grove, have since announced more stringent composting standards for food packaging products containing PFAS. Specifically, beginning December 31, 2019 for BPI, and January 1, 2020 for Cedar Grove, products with more than 100 parts per million (ppm) fluorine will no longer be certified compostable and will not be accepted at their facilities.

The New Food Economy article noted that the molded fiber products tested were found to have an average of 1,670 ppm fluorine. Until the new standards take effect, molded fiber with the current levels of FDA approved PFAS will continue to be accepted in composting sites.

What’s Next?

Trending consumer demands, legislation, or sustainability concerns may require some businesses to source alternative products.

At this time there are no alternative bagasse or molded fiber products without PFAS, but manufacturers are quickly researching and testing alternatives.

Though progress will vary by manufacturer, it is likely that an alternative molded fiber or bagasse product will not be available until sometime in 2020.

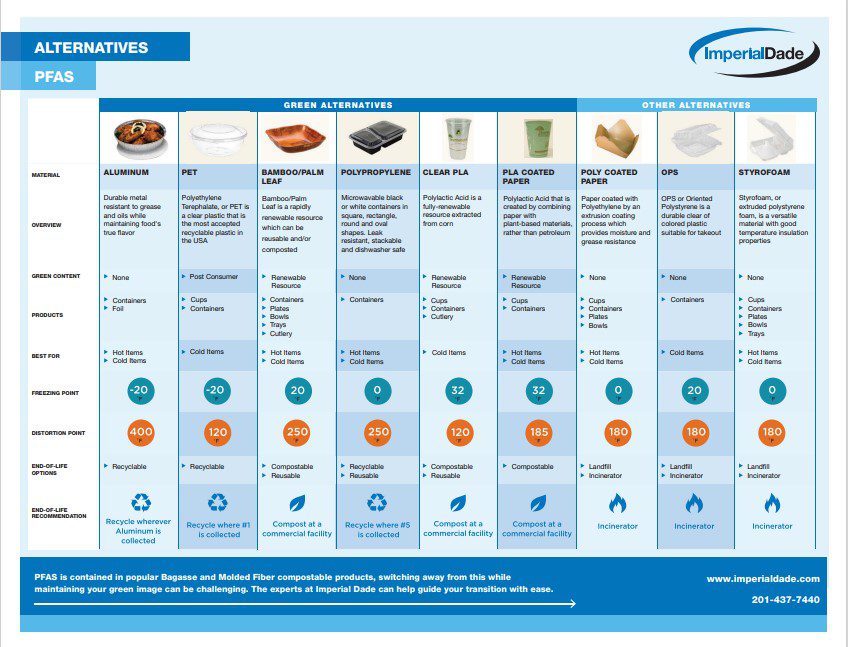

If you are looking for an alternative product today, there are several other alternative food packaging materials from which to choose.

Food Packaging without PFAS

The best PFAS-free food packaging:

- Bamboo

- Clear PLA

- PLA Coated Paper

- PET

- Aluminum

- Polypropylene

- Poly Coated Paper

- OPS

- Foam

1. Bamboo

Bamboo is a rapidly renewable resource, making it the most environmentally friendly alternative. It is used for cutlery or containers.

Advantages:

- Compostable

- It is a clear signal to consumers that you value sustainability

Disadvantages:

- When broken, bamboo can have sharp edges

2. Clear PLA

PLA, also known as polylactic acid, is a fully renewable resource extracted from corn. It is used to make compostable cold cups, containers, and cutlery.

Advantages:

- Compostable

- Reusable by the consumer

Disadvantages:

- PLA is not microwaveable or ovenable

3. PLA Coated Paper

PLA is used as an impermeable liner in paper cups and containers to keep the paper from getting soggy.

Advantages:

- Compostable

- PLA is soak through resistant. The plant-based resin acts as a barrier which prevents the paper part of the container from absorbing the liquid and becoming soggy or leaking.

Disadvantages:

- Not microwaveable or ovenable

- Has poor heat transfer, causing the exterior of the container to become hot to the touch

4. PET

PET, or polyethylene terephthalate, is made from plastic number one. It is used for cups and containers.

Advantages:

- Widely accepted for recycling

- See-through packaging alternative

Disadvantages:

- Low heat tolerance

5. Aluminum

Aluminum is a thin metal material that is used for containers.

Advantages:

- Safe to be used in the oven and in the freezer

- Good grease and liquid control

- Recyclable after being washed

Disadvantages:

- Not microwave safe

- Sharp edges which can cause injury to consumers

- The exterior of the product can get very hot and pose a burn risk to your employees and customers.

6. Polypropylene

Polypropylene is made from plastic number five. It is used for cups, containers, and cutlery.

Advantages:

- Recyclable

- Microwave-safe and dishwasher-safe

- Reusable by the consumer

- Great grease and liquid control

Disadvantages:

- Not the most widely accepted plastic by curbside recycling programs.

7. Poly Coated Paper

Poly Coated paper is flat paperboard lined with a polyethylene film. It can be used for hot and cold cups or containers.

Advantages:

- It is coated with polyethylene to provide good grease and water resistance

Disadvantages:

- Not recyclable or compostable because of the polyethylene coating

8. Oriented Polystyrene

Oriented Polystyrene, or OPS, is made by stretching extruded polystyrene film. It is used for containers.

Advantages:

- Offers see-through or colored alternatives

- Strong

Disadvantages:

- Brittle and is more likely to shatter

- Made from polystyrene, plastic number six, making it difficult to recycle

9. Foam

Foam, or expanded polystyrene, is the least environmentally friendly alternative. Foam is made from plastic number six. It can be used for cups and containers.

Advantages:

- Grease resistant

- Good insulation

Disadvantages:

- Foam is difficult to recycle

Final Thoughts

Until an alternative is developed, molded fiber and bagasse products require PFAS to resist liquid and grease.

As of August 2019, the PFAS chemicals being used in food packaging are still approved by the FDA.

Since the recent news releases, EBP has reached out to all of its manufacturing partners that produce molded fiber and bagasse products, and they have confirmed that they only use FDA approved PFAS in their food packaging products.

The molded fiber and bagasse products being used today do meet the current compostability standards of Cedar Grove and BPI, but with the implementation of the new 100 ppm fluorine limit in 2020, molded fiber and bagasse products, as they are produced today, will not be accepted for composting after 2019.

If you are a business that is concerned about sustainability or driven by increased consumer demands, you may be thinking about switching to an alternative food packaging material.

Imperial Dade locations have a wide variety of alternative food packaging materials that can help your business remain as sustainable as possible even as regulations on foodservice packaging change. We’d love to help, whether you’re located in the United States, Puerto Rico, or the Caribbean.

To help you better understand some of the alternative food packaging materials, we put together a quick reference guide that compares alternatives that do not contain PFAS: