Winter weather is unpredictable. There’s just no knowing for sure how harsh it will be until we’re in the thick of it.

Last year, the foremost weather observatory in the US recorded a warmer winter than average, but sporadic weather meant that it also saw more cold fronts and above-average snowfall. In fact, winter snowfall totaled 65.6 inches, almost 25% higher than the 30-year average.

There’s really no telling how much snow we’ll get this year, but there’s no harm in preparing for the worst. In fact, the benefits greatly outweigh the drawbacks of adjusting your floor care routine for the winter.

For example, while ice melt and rock salt are key to lowering slip and fall risksin the winter, especially during times of heavy snowfall, these products are also harsh on your floors and equipment and can damage them if you don’t take the necessary precautions – like regular equipment cleaning and maintenance.

That being said, it is important to invest in winter floor prep essentials and a new routine; if you don’t, the consequences can be costly both visually and financially.

How to Avoid Floor Damage During the Winter

It’s no secret that the appearance of a facility’s floors has an impact on how people in the building perceive the overall cleanliness. Winter weather makes floor maintenance that much more challenging. Combat floor damage with the following recommendations from industry experts.

Perform A Scrub and Recoat

A scrub and recoat should be performed before the winter, acting as a preventative measure.

The best time to perform a scrub and recoat is at the end of fall, no later than mid-November. Really, you want to get it in before the weather really kicks in. If it gets cold, that will negatively affect how the floor finish adheres to the floor.

We recommend this as a winter floor care procedure because it allows you to build up a couple of protective layers, called “wear off” coats. They’re called wear off coats because you expect them to be diminished by general wear and tear that happens to your floors each winter.

3-5 wear off coats is enough to protect your floors from any deep stains or serious damage for the winter. For the step-by-step process follow our winter floor prep guide on how to get your floors winter ready with a scrub and recoat, where we cover how to do both a top scrub and a deep scrub.

If you miss the window for a scrub and recoat, you can try and perform the procedure during the winter, but it is not recommended. It will take significantly longer to dry, and you risk people tracking moisture across the floor before it cures. At the end of the day, missing the scrub and recoat means amping up your floor care procedures for the rest of the season.

Install Floor Mats at Entryways

Your facility needs a good matting system to stop ice melt and rock salt residue, along with moisture from snow and ice, at the door.

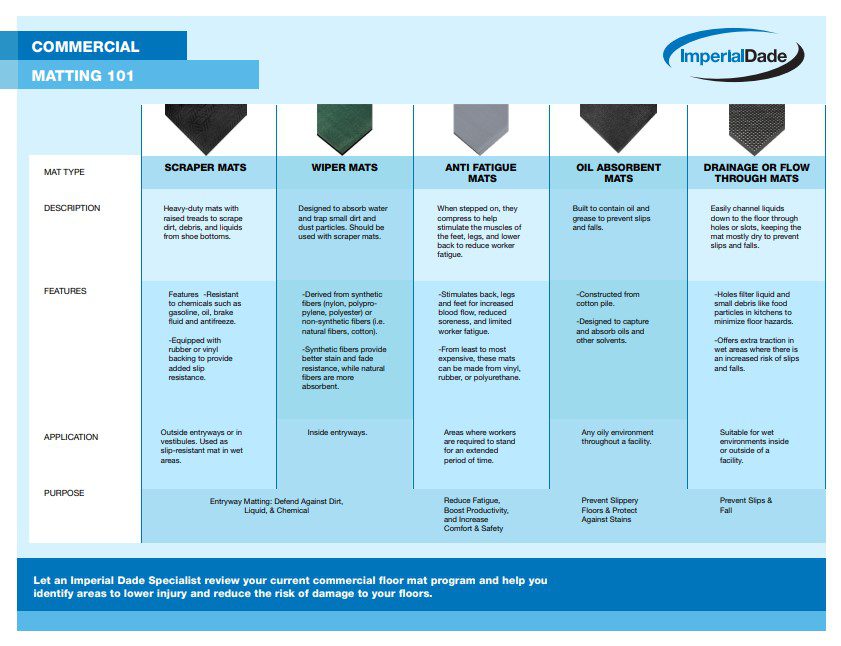

A matting system that is at least 15 ft long should trap about 90% of soil particles before they enter your facility. But, that’s just half the battle. In order to ensure that no ice melt residue or moisture gets tracked through the front entryway, your winter floor mats should include wiper, scraper, and wiper/scraper mats. This will ensure that as much ice melt residue and moisture as possible is removed from the bottom of people’s footwear as they enter the facility.

For more information on the best mats to protect your floors, download our FREE guide:

If you want to learn more about the different types of entry mats, take a look at our article on commercial floor mats. If you’re interested in learning more about how to properly utilize winter floor mats, check out our article on winter floor maintenance tips.

Use Floor Neutralizer to Remove Salt and Ice Melt Residue

If ice melt residue is still making its way into your facility, covering your floors in residue, then it’s time to break out the floor neutralizer.

Floor neutralizer is specifically designed to rid your floors of the white streaks and oily residue left behind by ice melt, because it is more acidic than floor cleaner.

Pro Tip: Floor neutralizer is different than neutral floor cleaner. A neutral floor cleaner is a perfect commercial cleaning product for daily floor maintenance, while floor neutralizers are specifically designed to dissolve ice melt chlorides, soap, and hard water films as well as scum, scale, and other organic residues. Floor neutralizer will both clean the floor and eliminate white residue so you only have to perform one floor care procedure.

On hard floors, floor neutralizers will help to prevent finish damage. When used on carpeted floors, it will help rinse salts from the carpet without damaging or degrading fibers. Do not try to use a cleaner with a high or low pH. Aside from potentially dangerous chemical reactions, high or low pH cleaning chemicals will not be effective at removing the residues. The pH of salts, which is the most common compound in ice melt, is very high.

Adopt a Routine Equipment Maintenance Schedule

Ice melt and rock salt residue can be left behind in the form of a white powder, oily film, or crystal, all of which are able to clog water lines and create back-ups in equipment tanks. On top of that, most popular brands of ice melt are made up of harsh chemicals, like chlorides, that can corrode and oxidize when they come into prolonged contact with metal.

The only real solution is to be diligent with your equipment maintenance and daily cleaning.

In the winter, it’s necessary to perform regular maintenance checks on equipment so that you can catch any problems and service them before they can turn into defects. Ideally, you’ll perform maintenance checks at the end of each day while cleaning the equipment.

Daily cleanings are the best preventative measure for equipment damage. Best practice would be to clean the equipment after each use. That may seem excessive, but the key to keeping equipment well-maintained is frequent and effective cleanings.

At the very least, we recommend cleaning equipment before storing it at the end of the day. There are two benefits to this:

- The ice melt residue will not be able to corrode and oxidize your equipment overnight while it sits in a closet

- You don’t have to spend time performing a maintenance check the next morning because already know that the equipment is clean and ready to go

Pro Tip: For an example on how to thoroughly clean a piece of equipment, check out our Steps to Clean an Autoscrubber Guide.

Final Thoughts

By neglecting to plan for winter floor care, you’re not only risking the appearance and condition of your floors, but you’re also inviting an increased risk of damage to your equipment as well.

Do yourself a favor and start prepping today! Don’t know where to begin? That’s ok, our experts here at Imperial Dade, are here to help!

We offer an unparalleled selection of equipment, materials, and supplies that will keep your floors and facility looking clean all year round. Sign up for a free consultation and we’ll have our experts review your facility, onsite or virtually, and look for gaps to diagnose exactly what products your facility needs.

Everything you need to know about resilient hard floors including how to maintain them for best results, troubleshooting, & more!

Check Out These Related Articles:

- Winter Floor Maintenance Tips: 4 Tips to Protect Your Facility’s Floors

- 4 Ways To Keep Your Floors Looking Their Best This Winter

- Neutral Floor Cleaner Vs Floor Neutralizer: When and How To Use

- 4 Steps to Remove Ice Melt Residue and White Streaks From Hard Floors

- Winter Floor Care: 4 Costly Floor Cleaning Mistakes to Avoid

- What is Ice Melt? Selecting The Best Ice Melt For Your Facility

- Floor Prep 101: Get Your Floors Winter Ready with a Scrub and Recoat

- Commercial Floor Mats 101: What are the Different Types of Floor Mats & Where to Use Them

- Winter Floor Maintenance Tips: 4 Tips to Protect Your Facility’s Floors

- How to Maintain an Autoscrubber in 10 Easy Steps: An Operator’s Manual

- Auto Scrubber Maintenance: How to Maintain a Floor Scrubber After Use